Calvi SpA’s manufacturing ability and quality are primarily based on the absolute reliability of its production installations: a range of machinery that is perfectly calibrated to the most complex manufacturing requirements.

ROLLING INSTALLATIONS

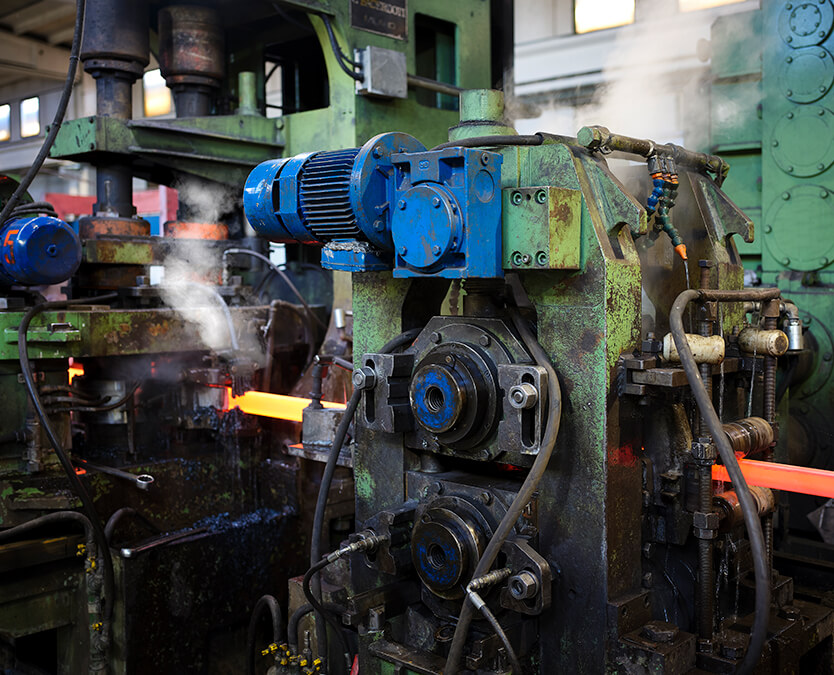

Induction rolling mill #1

A new generation induction furnace (1000 kW) and quick-change roll stands that allow for rapid machine set-up times make this installation one of the most innovative on the market. The mill also comes equipped with automatic coiling winders, allowing for coil-to-coil or coil-to-bar rolling, thus ensuring greater production flexibility and efficiency.

Induction rolling mill #2

The recent installation of a sixth rolling stand and a general revamp of the induction oven (2.500kW) ensure a greater uniformity of rolled products and a significant increase in production performance, making the induction rolling mill #2 the world’s top-performing mill for the rolling of special profiles in terms of tonnes produced / man-hours.

Turner’s workshop for tooling

Finally, the rolling facility also includes a turning workshop equipped with modern CNC turning machines, which can carry out rapid interventions on rolls and produce equipment for new profiles.

PREPARATION INSTALLATIONS

Heat treatment furnaces

Calvi SpA’s 7 batch furnaces are equipped with a resistance heating system with variable power and loading capacities. Controlled heating is carried out in an inert environment, in accordance with very precise heating of profiles to bring the material to its optimal condition in terms of its chemical-physical structure, for the subsequent forming operations. The furnace chambers have been designed to hold bars with a length of up to 13 m, and a loading capacity up to 30 tons. In certain cases they feature annealing thermal cycles lasting up to about 50 hours.

Mechanical and chemical pickling

The automatic sandblasting machines eliminate any traces of oxide originating from previous processing cycles, providing great support to operators thanks to their many functions and automated operations. Chemical pickling is only used with certain types of steel, and is carried out by immersion in an acid solution. The cleaning of metallic powders and oil residuals is completed with degreasing and rinsing.

DRAWING INSTALLATIONS

Automatic drawing for long bars

The twelve drawing lines designed internally, four of which 13 metre-long products, allow high performance drawing speeds (35 m/min) to be achieved with significant savings in terms of manufacturing scrap.

Combined drawing machines

Three combined drawing machines for the production of bar profiles from coils guarantee that the machines can be interchanged simply by changing the tooling.

Tooling workshop and Metrologic room

The dedicated workshop is equipped with computerised spark and wire erosion machinery which is used to produce the extremely hard, high-precision drawing dies required for the manufacture of complex drawn profiles with tight tolerances. The facility is also provided with computerised profile measuring systems and a laboratory where highly-experienced technicians carry out adjustments to drawing dies to ensure their optimal use on drawing lines.

FINISHING INSTALLATIONS

Straightening installation

Straightening is performed using 8 roller-type straighteners with varying features, 4 manual straightening presses, 1 STEP straightener and 2 modern automatic TWIN straighteners.

Detensioning installation

This operation applies an axial force of up to 350 tonnes to the bar to eliminate any tension generated during the drawing process. With the progressive diminution of tension, the bar becomes de-stressed and more workable, avoiding unwanted deformation during further manufacturing processes.